Table saws, at their core, consist of a high-speed motor, a flat table, and a saw blade. You can adjust the angle and depth of the cut by altering the blade height and location. Table saws are good for making rip cuts or other common cuts. There are many types of table saws. The sheer variety of designs was necessary to create tools that are optimized for specific use. We’re going to list the main types of table saws, their uses, and the pros and cons of each.

Portable Table Saws

Portable table saws for woodworking are by definition capable of being moved from one point to another, though they vary in portability. Several categories of portable table saws: benchtop saws, compact table saws, and Jobsite saws.

Benchtop Saws

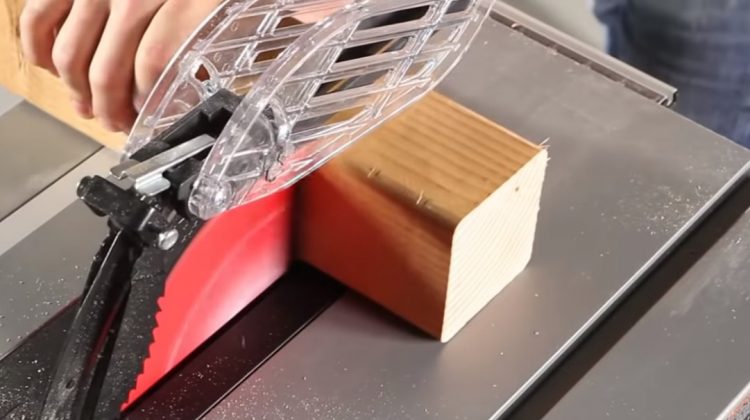

Benchtop saws are designed for sitting on your workbench. They are the smallest and lightest saws on the market. They’re powered by a 1.5 to 2 horsepower direct-drive universal motor. Know that you have to make sure the blade design matches the motor speed. In the case of a benchtop saw, a blade meant for fast, powerful motors won’t do much. (Put a benchtop saw blade on a cabinet saw, though, and you’ve just created a safety hazard.) Pay attention to the type and make of the blade because Dado blades won’t work on all benchtop saws.

Benchtop saws will clamp to almost any surface, and they’ll work equally well on any surface as long as it is level. Some manufacturers sell a separate stand for the portable benchtop saw. However, it isn’t as rugged as a Jobsite saw though it could stand in for one in a pinch.

These are typically the best table saw for beginners since they have the features new and light users need without anything they don’t. As the name implies, they don’t have a stand. They are often portable; there are benchtop saws you can load up and take to the craft fair and continue working, assuming you take all appropriate safety measures. However, benchtop saw is portable because they weigh so little that one person could pick it up and carry it off. A few, though, have carry handles or rolling frames; you can truly take it with you.

Benchtop saws have the lowest rip capacity of any type of saws on our list. They tend not to have as many functions. You can cut 2 by 4s and angles into plywood. The blades on benchtop saws can reach ten inches. Benchtop saws are too small to work with full-size material sheets. You have to be careful with the fence position and angles before you cut. Because they are cheaper, they tend to wear out faster. They’re more prone to damage and breakage. You’ll either have to know how to sharpen a table saw blade because you’ll be doing it often or where to order replacement parts on a regular basis if you’re using the saw often. Most of the benchtop table saw can be found for under $200 if you want any table saw in this price range for the small DIY task you can choose them.

You can probably only cut softwoods and plywood with benchtop saws. Being cheap, you may be charged a fortune for replacement parts or be unable to get the unit repaired at all. Conversely, they take up the least space. You can fit it on the corner of a workbench or store it on the shelf. Benchtop saws are the most economical choice if you rarely work with wood or aren’t sure if you’re going to keep up your new woodworking hobby. If you do become an advanced woodworker, the benchtop saw is still good enough for many basic tasks.

You can probably only cut softwoods and plywood with benchtop saws. Being cheap, you may be charged a fortune for replacement parts or be unable to get the unit repaired at all. Conversely, they take up the least space. You can fit it on the corner of a workbench or store it on the shelf. Benchtop saws are the most economical choice if you rarely work with wood or aren’t sure if you’re going to keep up your new woodworking hobby. If you do become an advanced woodworker, the benchtop saw is still good enough for many basic tasks.

In short, if you don’t really know how to use a table saw, you are best off getting a benchtop saw. It is a step up from the hand saw while being nearly as easy to use. It is good enough for making a spice rack or bookcase, but it won’t let you make furniture or cut new crown molding.

Compact Table Saws

Compact table saws are a little better than benchtop saws. They share the direct drive universal motor you see on benchtop saws. These motors aren’t as durable or quiet as induction motors but are a good overall value; they put out a lot of power given their price tag.

Compact table saws may or may not have stands, but they’re not as rugged as Jobsite saws. They may have a table, but it will be smaller than a full-sized table saw. Their rip capacity is certainly less than a stationary table saw like a cabinet saw. However, they can be pretty stable while making a rip cut.

Note: Pick A Saw just published the battle between Grizzly G0690 and G1023RL table saw you can check it 🙂

Compact table saws are considered portable because they’re made with the lightest materials and smaller motors, so you could, in theory, load them in your truck or carry it to the shed.

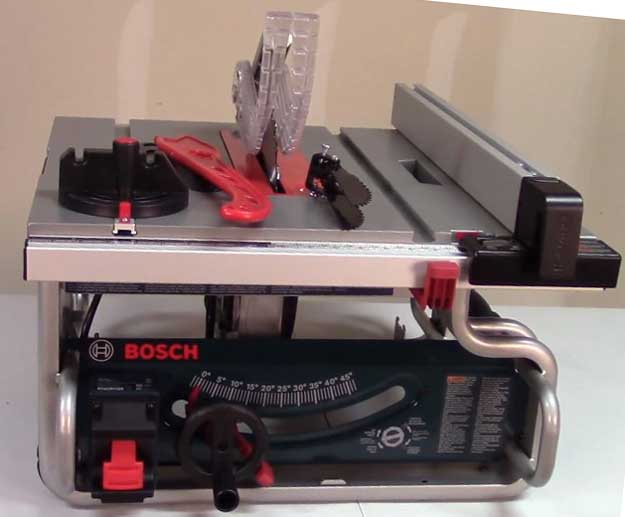

Jobsite Saws

Jobsite saws are those table saw designed for the small shops or the Jobsite. They’re more rugged than average. They balance functionality with portability and have more features than most benchtop saws. This ironically means they may be ideal for beginners who need more than the minimal features of tabletop or portable saws. For example, their portable stand means you can move it from one place to another as like the storage shed to the garage.

It is easier to take the Jobsite saws with you to camp or where you’re building a treehouse. Their greater durability means it is less likely to be destroyed if bumped by the car. In other cases, the built-in features like riving knives and dust collection ports make them an upgrade from benchtop saws. These types of table saw can be found for under $500. Moreover, these saws tend to have greater rip capacities and more reliable fences. However, these fences are intended for professionals and not for beginners.

Stationary Table Saws

Stationary table saws are designed to stay in one place. There are three subcategories of stationary stable saws: contractor saws, cabinet saws, and hybrid saws. You need to know how to change a table saw blade with all of these saws since they’re designed to last a long time and perform various jobs.

Contractor Table Saws

Contractor table saws are better than job site saws, though the terms contractor saws and Jobsite saws are often used interchangeably. Contractor saws are made for professionals, though they’re cheaper and smaller than cabinet saws. Contractor saws have more robust motors and larger table areas than portable table saws. The earliest models had outboard induction motors. Induction motors tend to be quieter than the high-power motors you see in cabinet saws.

They may have one or two belts driving the blade; when there are two such belts, they cut faster through thick boards. The motor often hinges off the rear of the saw to give you as much workspace in front of the saw as possible.

The downside of this design is that the dust created by the woodworking will clog up the motor unless the motor is specially sealed from dust or you have an excellent dust collection system.

The more powerful motor tends to create more vibration, so you have to be careful when doing accurate work. Their longer belts aren’t a problem per se, but finding replacements isn’t as easy as it would be with portable table saws or heavier duty saws constantly run by professionals.

Contractor table saws are typically so heavy you can’t lug them to the worksite. Instead, they’re best kept in the workshop or moved to a construction site where they’re used regularly until the project is over. Their performance will be better than any portable saw. And they’re cheaper than other types of stationary saws.

Cabinet table saws are full-sized saws. They’re what you’d need for making large pieces of furniture like cabinets, hence the name. Because they’re so big and powerful, they tend to be expensive. They often require a 220-volt connection to run. They also tend to be enclosed in a cabinet, though hybrid saws may have that feature, too. They come with every feature you’d want. They’re robust. Because you’re paying so much for the cabinet table saw, they tend to have top-notch dust collection systems.

Cabinet Table Saws

Cabinet table saws are the most precise and accurate. Most cabinet table saws come with trunnions that let you adjust their height or tilt, and they can be set to stay that way while you work. Their three to five horsepower motors are going to rip through almost any material. You know it will cut through hardwoods, thick lumber, and pressure-treated lumber.

Their combination of power and accuracy is typically the result of two or three V-shaped belts that drive the blades. This minimizes the amount of vibration in the blades, increasing the accuracy of the cut. The other benefit is increased durability, and that’s not counting the cabinet that helps it come in at up to 500 pounds. For example, the cabinet table saw is going to have steel parts, where the portable bench saw uses aluminum.

Hybrid Table Saws

Hybrid table saws are a relatively new form of table saw on the market. They were developed to combine the best features of contractor and cabinet table saws.

Hybrid table saws are most similar to contractor saws. They’re similar in price to contractor saws and cheaper than cabinet saws. Hybrid saws are typically more powerful than contractor saws; their inboard belt drive induction motors generally have 1.5 to 2 horsepower.

Conversely, this means you can power it with your standard 110-volt power outlet. They have more functions than a contractor saw, too, but they lack the full set of features cabinet saws have. For example, they almost always have a good dust collection system. They often have open stand legs, though this isn’t a defining characteristic. They’re a decent choice for advanced hobbyists when you’re ready to upgrade your benchtop table saw.

Summary

How can you find the best table saw for your particular application? Understand your skill level. Know what you intend to do with the saw. And set your budget. Then you’ll be able to find the best table saw for your needs because you won’t buy a saw that’s more powerful or expensive than what you really need.